Photo © Joke ibens

To the outsider, engineering and imagination seem to be a not-so-obvious combination. But nothing could be further from the truth, as soon becomes clear during a conversation with Tom Molkens. In 1998 Tom founded the engineering consulting company Stubeco with a clear mission to provide specialized structural design analysis services. Empowered by a creative vision, Stubeco focused on realizing inventive building concepts by fully exploiting the possibilities offered by modern structural design analysis software.

Early 2016, Stubeco was integrated within Sweco Belgium. As a Sweco Senior Project Expert, Tom Molkens assesses the feasibility of complex building projects and devises creative structural concepts. Also, he closely monitors the evolutions in the area of structural design analysis, in particular as they relate to fire resistance, earthquake resistant design, probabilistic design and progressive collapse of building structures.

It all starts with a simple idea

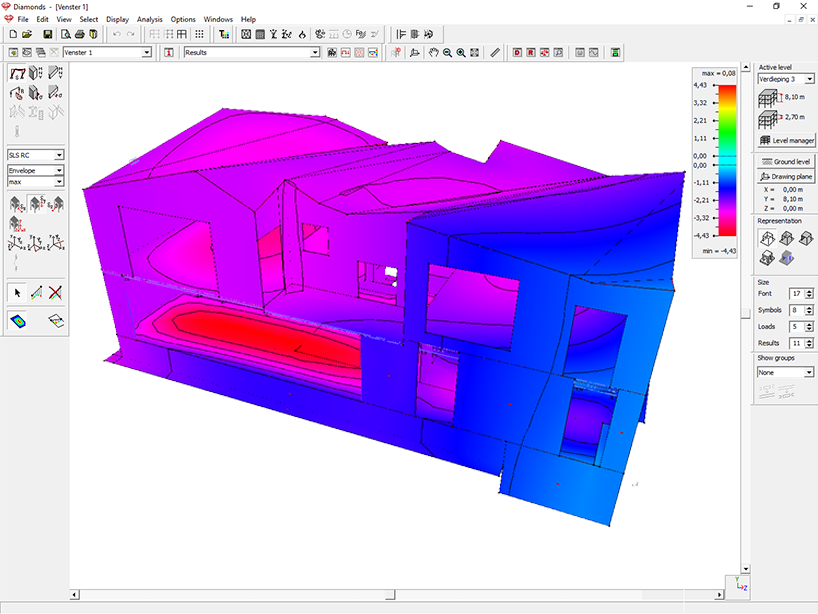

For the renovation of a typical 1960s villa into the light-filled family home of architect Joke ibens, Stubeco developed a highly original structural concept. A simple idea provided the basis for that concept: if you cut a few openings in the upright surfaces of a shoe box, that box can perfectly stay upright - even if you put some extra weight on top of it. As long as its upright surfaces provide a sufficient amount of stiffness, a shoe box has an amazing load bearing capacity.

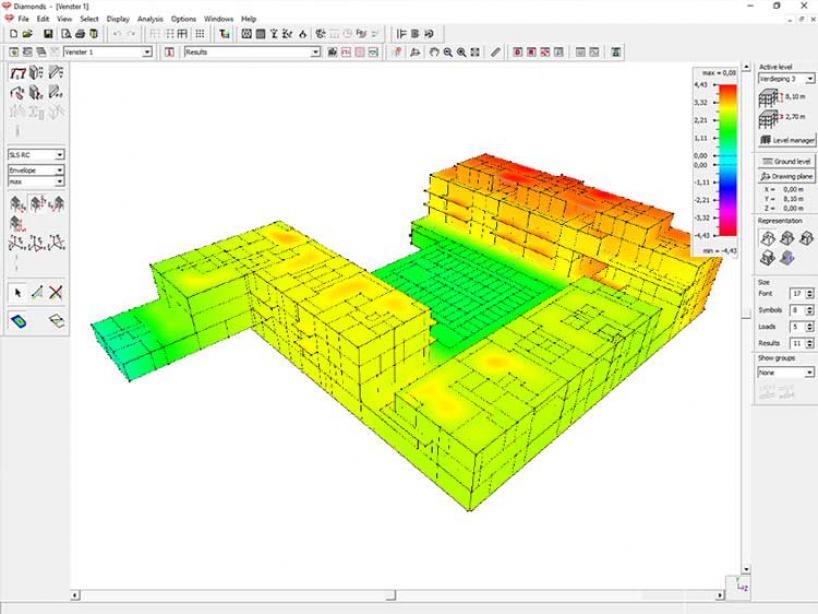

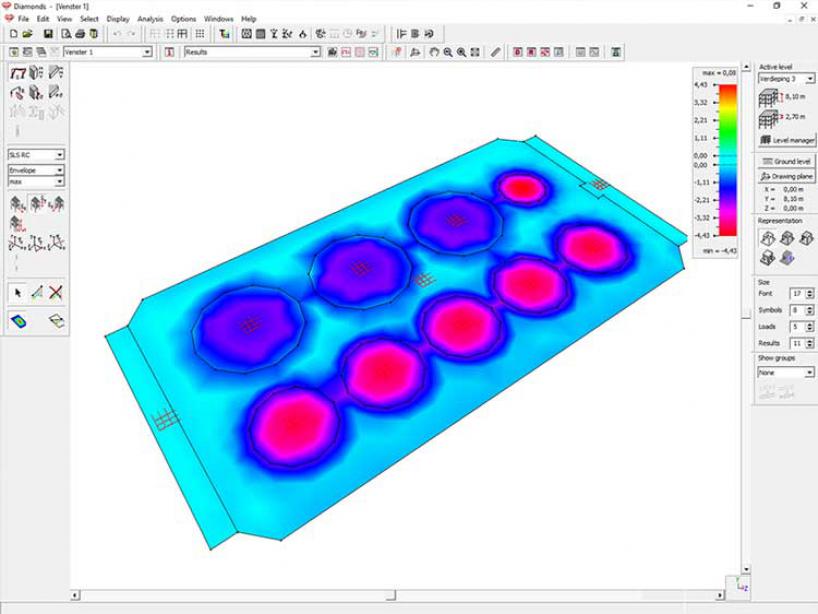

The shoe box idea exemplifies the concept of rigid concrete walls. If such walls are built on top of an existing masonry structure (which has a much lower stiffness compared to the concrete walls), superstructure loads are evenly spread over the substructure, and unique things come within reach.

Creating new possibilities

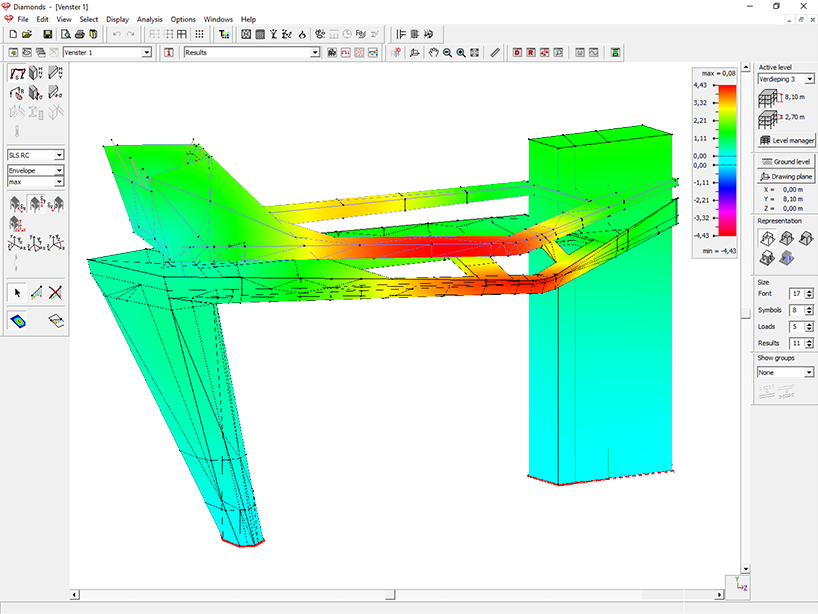

"By responding to the high stiffness differences between the substructure and superstructure, engineers get a grip on the structural design of the building," says Tom Molkens. “It enables us to make the substructure and superstructure work together in the best way possible and to transfer structural loads towards the foundation level through a few strategically positioned concrete columns. That's all it takes to create a lot of new possibilities and change a 1960 villa into an open and light-filled family home.

Of course, many questions remain unanswered. Will the existing masonry be able to handle this? Will the foundations be able to handle this? Where can substructure openings be created to realize light-filled living spaces? Such questions cannot be answered without the use of 3D structural design analysis software.”

"Isostatic/hyperstatic structural analysis based on rigid supports is a thing of the past," Tom Molkens continues. "In practice, there is no such thing as a 100% rigid support. Using structural design analysis software to actively manipulate the relative stiffness of different building elements offers numerous possibilities that did not exist before. Personally, I often find it very worthwhile to observe buildings while they are being demolished. It is surprising how parts of a building remain standing even after a significant part of the substructure has been removed. That tells a lot about how structural building components work together. And that's precisely what I try to respond to by making sensible use of 3D structural design analysis software."

Thinking in 3D

"Another thing that makes the ibens house very special is its roof structure, a folded concrete slab that adds an incredible amount of stiffness," says Tom Molkens. "If you want to take that stiffness into account in a realistic way, you need to think in 3D. That’s why we integrated the entire roof structure into the Diamonds 3D analysis model, enabling us to evaluate both the stability and load-bearing capacity of the entire structure and to design concrete reinforcement."

The concrete walls and roof structure of the new ibens family home were cast on site. A prefab solution was considered as well but posed too many challenges. As the roof surface does not show any regularity at all, installation of prefab roof panels would have required an expensive crane structure. Also, the roof elements were designed to form a stiff ensemble with the superstructure. Working with individual prefab elements would therefore require a formwork to support these elements during the construction phase, until all connections between the roof panels have been realized. Casting concrete on site proved to be the most logical approach to build the concrete roof structure and superstructure.