If the Rotterdam Market Hall’s iconic shape captures your imagination, then the inside of this apartment building covering a fresh food market will do so even more. The central Market Square offers a spectacular view of the Horn of Plenty, Arno Coenen’s impressive artwork. Brightly colored giant fish, fruits and vegetables amaze every single visitor.

The Rotterdam Market Hall, including a view on the Horn of Plenty artwork decorating the inside of the building © Ossip van Duivenbode

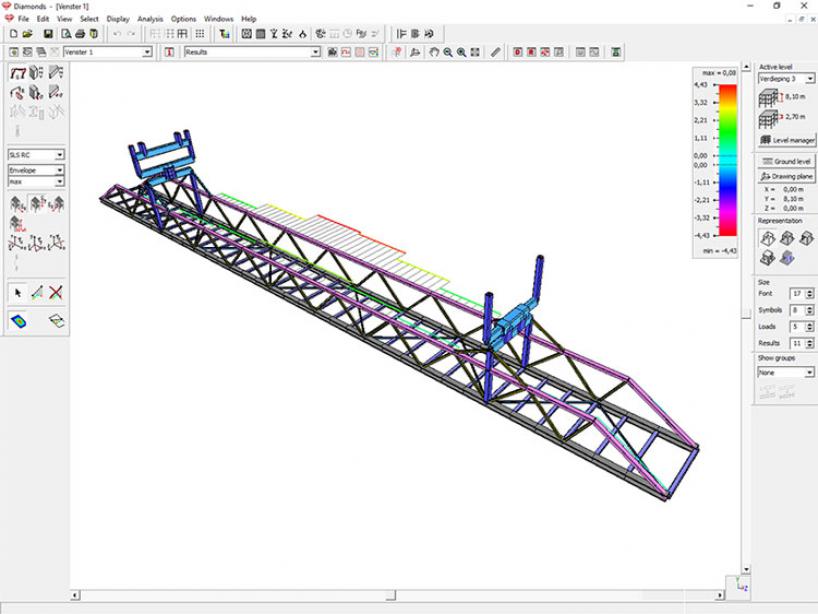

Top view of the maintenance platform, including the yoke with pendulum arms (left). © Marcel van Odenhoven

And while admiring this splendid ‘Rotterdam Sistine Chapel’ the size of two football fields, do you notice the mobile maintenance platform 30 meters above ground level? If so, it will become clear how the cable-net facades and the artwork surface are maintained from the inside.

Safety and reliability come first

The maintenance platform has been manufactured and built by Manntech Gevelinstallaties. This company, based in Moerdijk (The Netherlands), has been active for more than 60 years in the area of design, manufacturing and installation of facade maintenance systems. Staalbouwkundig Adviesburo van Odenhoven (Heijningen, The Netherlands) has been using BuildSoft’s structural analysis software Diamonds to engineer the truss bridge that supports the platform.

The truss bridge that supports the maintenance platform is suspended from overhead tracks along the entire length of the Market Hall. A trolley on top of the platform provides the maintenance team with access to the upper part of the artwork surface. The lower parts of the inner facades can be reached from within a nacelle that is suspended with cables from a mobile undercarriage at the bottom of the truss bridge. This creates a maintenance system that allows to handle the entire surface of the inner facade.

“What makes this project very special” says Marcel, “is the nacelle that can tap into rails that follow the contours of the curved facade. By slackening the cables through which the nacelle is suspended from the mobile undercarriage, that nacelle will move at a fixed distance along the inner facade and will subject the truss bridge to an oblique tensile load. The direction of that load will change as the nacelle moves along the facades.”

Playing a creative game

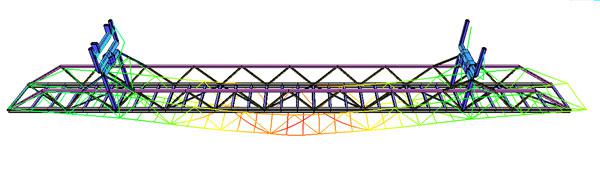

In spite of the fact that safety always is a key factor with this kind of project, keeping horizontal deformations under control proved to be extremely important for the Market Hall maintenance platform. Under no circumstances should that platform exert a pressure on the inner facade when the nacelle subjects the truss bridge to an oblique tensile load. The horizontal flexibility of the truss bridge should thus be limited, and that was achieved through a number of braces that deliver the required rigidity. “The nice thing about a 3D structural analysis model that you build with Diamonds” says Marcel, “is that you can easily identify the source of any problem and can then solve it quickly as well by adding stiffness where it is needed most. That’s the typical game any structural engineer should be playing, and I love to play that game within a working environment that gives me the freedom I need to come up with creative solutions.

3D Diamonds model of the steel truss bridge, visualizing horizontal deformations for a specific load case

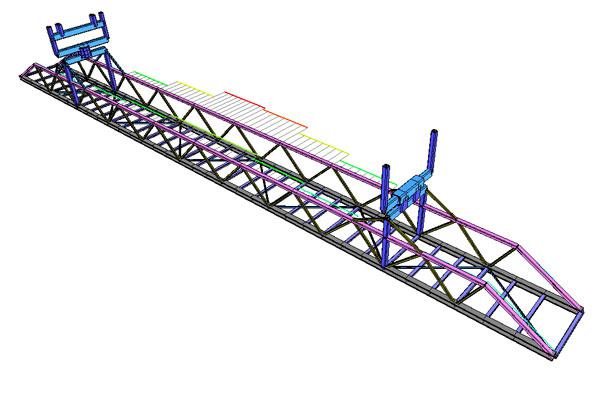

3D Diamonds model of the steel truss bridge, visualizing buckling check results for compression members

A particular problem that is usually encountered with this type of structure relates to the buckling check of compression members along its upper edge. The edge beam diagonals, which are laterally supported by horizontal structural members in the bottom plane of the bridge, provide an elastic support for the upper edge. As a consequence, its out-of-plane buckling length will be smaller than the distance between the yokes. This reduced buckling length can easily be defined in Diamonds, in order to perform a more realistic buckling resistance check that fully complies with Eurocode 3.”