A fresh produce distribution center in Breda

The engineering department selected a recent project from a vast pool of national and international projects: a fresh produce distribution center in Breda, the Netherlands.

WDP is a leading player specializing in the development and lease of logistics real estate. For over 10 years, Willy Naessens Industriebouw has worked on numerous projects on behalf of WDP, according to Chris Verbrugghe (who joined the engineering department at headquarters more than 20 years ago). It is no coincidence, therefore, that the new distribution center for The Greenery (an international sales organization specializing in fresh fruit and vegetables) is to be found next to an earlier project of Willy Naessens Industrial Buildings for WDP: the 80,000 m2 LIDL distribution center in Breda.

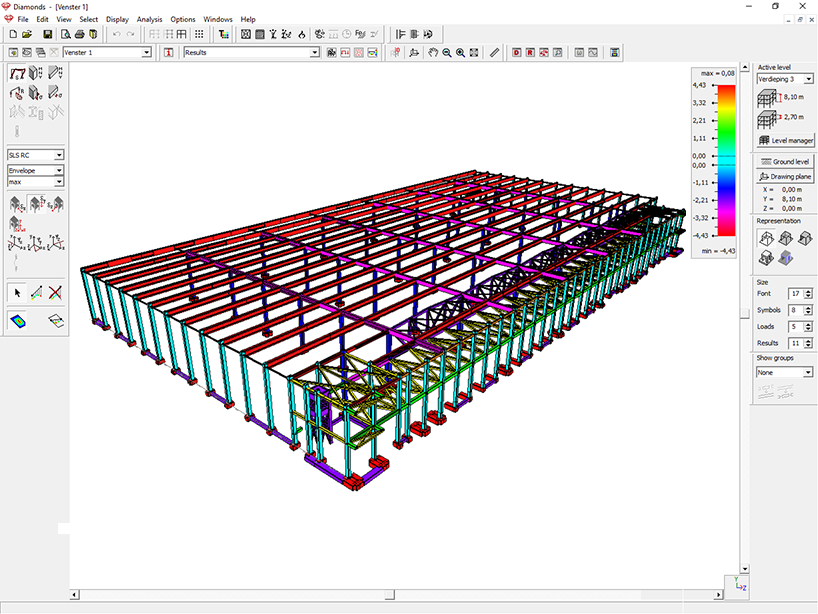

"Normally, our Dutch colleagues would have been responsible for the structural design of this building. But due to our rapid growth in the Netherlands, we have followed up on this project from Belgium. This logistics building is over 12 meters high and has a rectangular floor plan 84 meters wide and 160 meters long. Because of the relatively poor soil conditions, this concrete building is founded on piles. Concrete trusses are placed every 6 meters and carry a steel deck roof structure. These concrete trusses rest on beams which, in turn, are supported by concrete columns in a pattern measuring 12 meters by 22.80 meters.

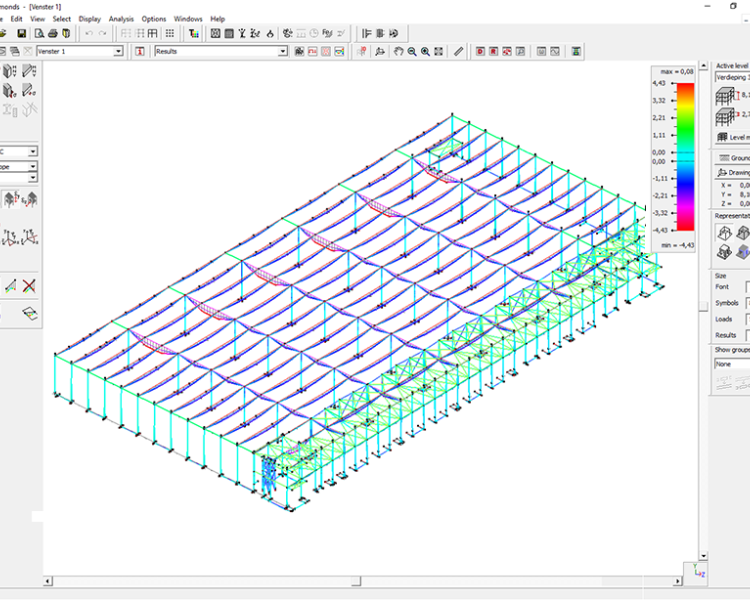

There is a mezzanine at the front, and office space is provided at both corners of the building. To guarantee a free height of 5 meters in the warehouse and to keep the mezzanine floor level below 6 meters, a 22.80-meter-long truss was planned at this location. The bottom chord of this 6-meter-high truss acts as the mezzanine's floor beam, while the top chord acts as a roof beam. This construction enabled us to limit the floor beam’s height to half a meter for a total span of 22.80 meters and, in doing so, comply with all spatial boundary conditions.

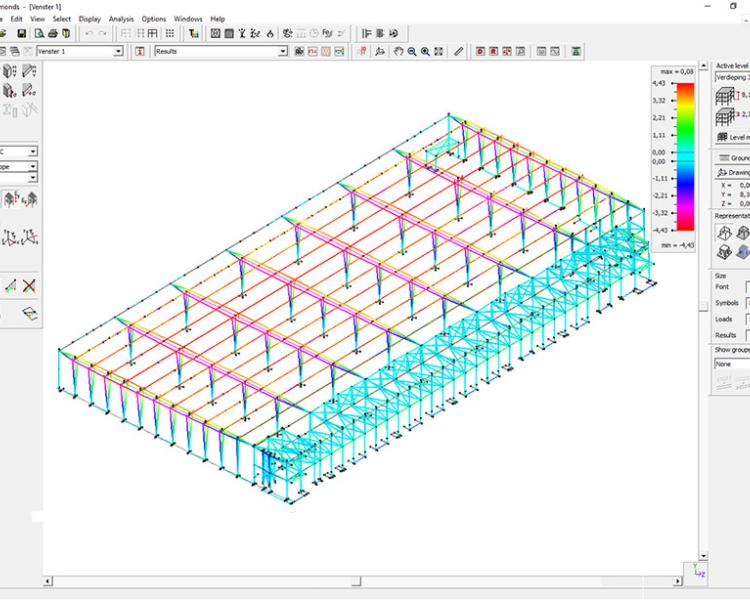

This warehouse is pretty representative of the constructions we realize with Willy Naessens Industriebouw. I’m referring in particular to the modular use of precast elements, such as concrete columns clamped at foundation level and concrete beams hinged at both ends. 3D structural analysis with BuildSoft’s Diamonds software is, therefore, perfect to help us design the building structure most efficiently and economically. And the ability to calculate both steel and concrete elements in a single structural analysis model is a strong plus.

With all the productivity tools that Diamonds has on offer, we could deliver a validated structural design within one week. Amongst others, we made intensive use of the possibility to import load combinations into the software. Taking into account various factors, including the country where the building is to be realized or the presence of special loads (such as crane loads, for example), we have developed a series of fixed load combinations over the years. Because we can easily import those load combinations into Diamonds, it becomes straightforward to standardize our way of working. In a growing organization that operates at different locations, that is a vital aspect of working efficiently.

And then, of course, there are the extensive structural analysis possibilities offered by Diamonds. Not only for the calculation of deformations in serviceability limit states or the calculation of internal forces in ultimate limit states (normative for the dimensioning of pre-stressed concrete elements) but also when it comes to the various code checks. Using Tekla Structures macros, our team converts the reinforcement sections calculated by Diamonds into a practical reinforcement plan.

Keywords such as speed, simplicity, and completeness jump to my mind whenever I think of BuildSoft's Diamonds structural analysis software. And when I talk about completeness, I am referring in particular to the flexible Smart Reporter’s possibilities. We use the Diamonds Smart Reporter to create a PDF file for each project. That enables us to easily share all aspects of the structural analysis model with the technical inspection agency, starting with the geometry and loads models up to the actual structural analysis results."